Leaded Resistors

Carbon Film

Resistors

Precision Metal

Film Fixed

Resistors

Metal Oxide Film

Resistors

Fusible

Resistors

Wire-Wound Fixed

Resistors

Terminal Type MO

Resistors

Metal Glazed

Film Fixed

Resistors

Anti-Surge Fixed

Resistors

Cement

Resistors

|

Why TAI?

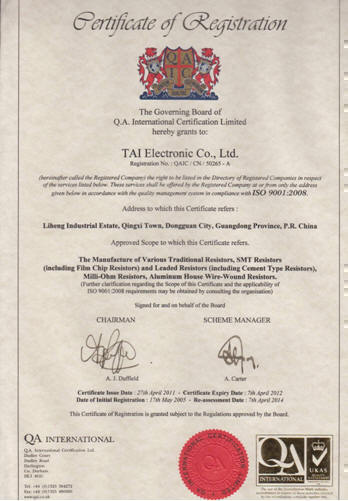

We are Taiwan company a

leading professional resistors manufacturer for more

than three decades, DongGuan TAI Electronics Co. Ltd is

marketing all types of resistors, including carbon film

resistors, metal film resistor, wire-wound resistors,

cement/ceramic resistors, high power resistors, aluminum

housed wire-wound resistors, non-inductive resistors,

SMD resistors and other special resistors.

We can guarantee strict quality control and delivery

time. Our main materials are from Japan and Taiwan,

ensuring product quality and long-life span,

professional engineers and experienced workers are

employed to guarantee production standardization and

good quality and ensure we meet ISO 9001:2008,

ISO14001:2004; CE, RoHS, UL and CQC standards and

maintain a defect rate of only 0.01 percent.

|

|

Quality Strategy: ISO9001:2008

Production

activity and product resulted to be

Produce high

quality resistor production according

to customer's requirement.

Seriously applying quality management system of

ISO 9001:2000, meet all of customers requirement

and current rules.

Improve quality management system continuously

specially on product and its productivity.

Determined and evaluate the quality target

gradually.

This quality policy will be evaluated gradually,

at least on Management evaluation.

|

|

|

|

Environmental Management: ISO14001:2004.

Production

activity and product resulted to be continuously

friendly environment.

Avoid environment pollution impact such as :

Natural energy resources pollution (land, water,

air)

Emission pollution on transportation

Pollution by any chemical stuff and poison

dangerous materials.

Economize on using the natural resources such as

electricity, papers and water.

Environment activity has to follow valid company

and government's rules.

Implement environment activity, in order to

achieve the environment's aim.

Ensure all production materials is not contained

dangerous chemical stuff.

Ensure all product resulted is free from

dangerous chemical stuff.

Make socialization, actualization and

documentation of environmental activity

internally (to employee) and externally (public) |

|

|